Graphite Blocks for Kiln Supporting Rollers

Price 2000 INR/ Piece

MOQ : 1 Piece

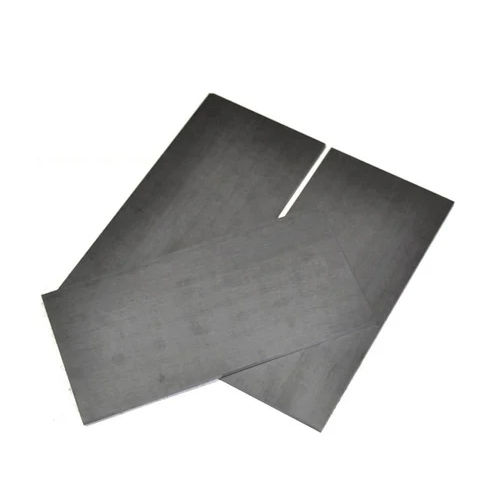

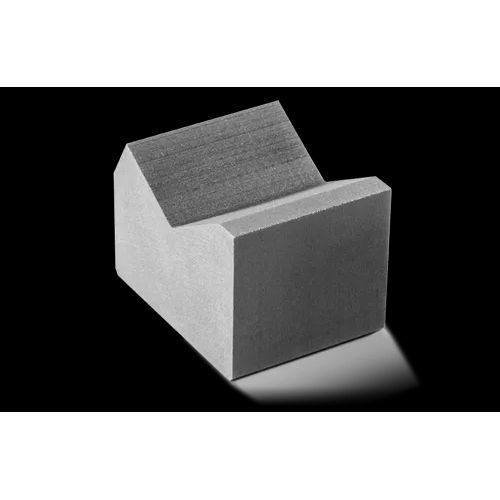

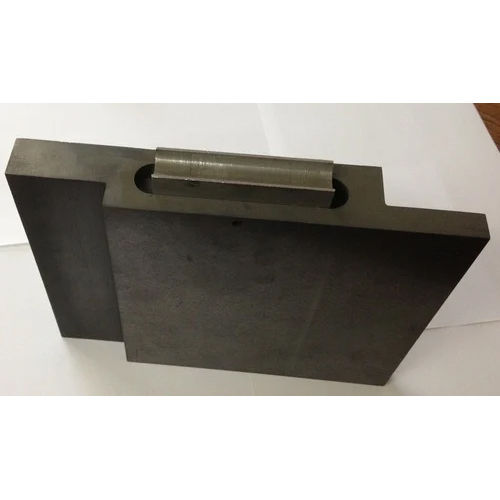

Graphite Blocks for Kiln Supporting Rollers Specification

- Usage

- Kiln Supporting Rollers

- Material

- Graphite

- Size

- Different Available

- Shape

- Rectangular

- Product Type

- Graphite Blocks for Kiln Supporting Rollers

- Color

- Grey

Graphite Blocks for Kiln Supporting Rollers Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 7-10 Days

About Graphite Blocks for Kiln Supporting Rollers

Exclusively crafted in India, our Graphite Blocks for Kiln Supporting Rollers are designed to deliver unmatchable performance in diverse industrial environments. Made from high-grade graphite, these lofty rectangular blocks are available in multiple sizes and a classic grey hue to match specific requirements. The scarcity of superior graphite is highlighted in our product, ensuring longevity, cost savings, and best-in-class efficiency. As a trusted exporter, manufacturer, and supplier, we guarantee robust support and reliability, making your kiln operations truly unmatchable.

Extra Features and Application Places

Our Graphite Blocks boast excellent thermal conductivity and resistance to high temperatures, making them especially suitable for kiln supporting rollers in cement plants, ceramics, and refractories. These blocks are engineered for heavy-duty use, ensuring minimal maintenance and longevity while handling extreme conditions. The versatility in sizes and shapes allows tailored application across various industrial sectors, guaranteeing seamless integration and elevated performance wherever kiln support is crucial.

Packaging, Export Markets, and Payment Terms

Each Graphite Block is packaged securely, ensuring every sale price fits the estimate and quality promised. Blocks are carefully handed over in sturdy pallets and crates for safe delivery. We cater primarily to main export markets in Asia, Africa, and Europe. Payment terms are flexibleadvance, Letter of Credit, or other negotiated methodsensuring transparent deals for every customer. Quality assurance is maintained throughout the shipment and delivery process, reflecting our commitment to satisfaction.

Extra Features and Application Places

Our Graphite Blocks boast excellent thermal conductivity and resistance to high temperatures, making them especially suitable for kiln supporting rollers in cement plants, ceramics, and refractories. These blocks are engineered for heavy-duty use, ensuring minimal maintenance and longevity while handling extreme conditions. The versatility in sizes and shapes allows tailored application across various industrial sectors, guaranteeing seamless integration and elevated performance wherever kiln support is crucial.

Packaging, Export Markets, and Payment Terms

Each Graphite Block is packaged securely, ensuring every sale price fits the estimate and quality promised. Blocks are carefully handed over in sturdy pallets and crates for safe delivery. We cater primarily to main export markets in Asia, Africa, and Europe. Payment terms are flexibleadvance, Letter of Credit, or other negotiated methodsensuring transparent deals for every customer. Quality assurance is maintained throughout the shipment and delivery process, reflecting our commitment to satisfaction.

FAQs of Graphite Blocks for Kiln Supporting Rollers:

Q: How do these graphite blocks benefit kiln supporting rollers?

A: The graphite blocks provide unmatchable heat resistance and durability, reducing wear and maintenance costs for kiln supporting rollers, ultimately leading to substantial savings.Q: What is the process for ordering graphite blocks from India?

A: To order, contact the exporter, manufacturer, or supplier directly. Choose your required size and specifications, confirm terms, and the product will be shipped after payment authorization.Q: When are graphite blocks most commonly replaced in kiln systems?

A: Replacement is typically necessary during routine maintenance or whenever wear compromises performance, ensuring best support and longevity for kiln supporting rollers.Q: Where can these graphite blocks be used apart from kiln supporting rollers?

A: While highlighted for kiln use, these blocks are also suitable for supporting rollers in cement, ceramics, and refractory sectors where high temperature and reliability are essential.Q: What extra features distinguish your graphite blocks from others?

A: Our graphite blocks offer lofty thermal conductivity, scarcity-driven quality assurance, and fitting versatility, making them the best choice for demanding industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Graphite Plates and Blocks Category

Graphite Guide Blocks For Glass Industry

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Size : Different Available

Shape : Rectangular / Custom

Material : High Strength Graphite

Carbon Graphite Blocks

Price 350 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Size : Different Available

Shape : Rectangular

Material : graphite

Graphite Block for Kiln Inlet

Price 1800 INR / Piece

Minimum Order Quantity : 1 Piece

Color : grey

Size : Different Available

Shape : Rectangular

Material : graphite

Molded Graphite Blocks

Price 500 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Grey

Size : Different Available

Shape : Rectangular

Material : Graphite

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese