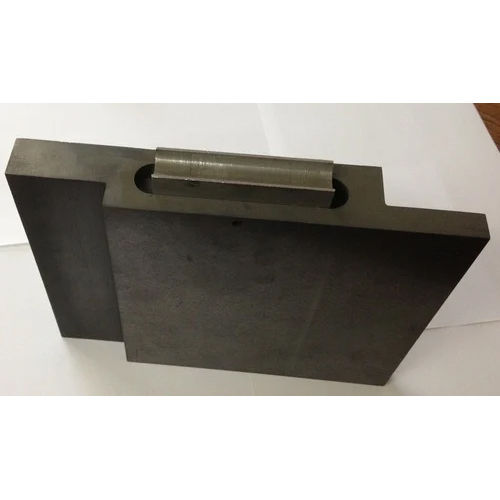

Graphite Block for Kiln Inlet

Price 1800 INR/ Piece

Graphite Block for Kiln Inlet Specification

- Usage

- Industrial

- Material

- graphite

- Size

- Different Available

- Shape

- Rectangular

- Product Type

- Graphite Block for Kiln Inlet

- Color

- grey

Graphite Block for Kiln Inlet Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 7-10 Days

About Graphite Block for Kiln Inlet

Key Features & Suitable Usage of Graphite Block for Kiln Inlet

Graphite Block for Kiln Inlet boasts high thermal stability and reduced wear, making it ideal for industrial kiln operations. Its rectangular shape and grey color provide seamless integration, while multiple available sizes cater to varied industrial needs. Designed specifically for industrial usage, these blocks excel in environments requiring eminent conductivity and resilience. Manufacturers and users benefit from enduring performance during continuous kiln processes, ensuring a reliable operational flow.

Export Markets, Payment and Stock Readiness

Stock ready Graphite Block for Kiln Inlet is supplied to main export markets globally. Customers in regions such as the Middle East, Asia, and Europe benefit from competitive list prices and reliable shipment details. Payment terms are flexible, designed for convenience and efficiency. Available through the FOB port in India, our export process ensures timely and secure delivery for clients seeking decorated industrial solutions with swift supply readiness.

FAQs of Graphite Block for Kiln Inlet:

Q: How is the Graphite Block for Kiln Inlet used in industrial settings?

A: Graphite Blocks for Kiln Inlet are typically installed where high temperature and thermal stability are required, providing a resilient barrier inside industrial kilns.Q: What are the main benefits of using graphite material for kiln inlets?

A: Graphite material offers reduced friction, excellent heat resistance, and prolonged durability, ensuring optimized performance and longevity in industrial operations.Q: Where can I source different sizes of Graphite Blocks for my kiln inlet needs?

A: Various sizes of Graphite Blocks are available from eminent exporters, manufacturers, and suppliers based in India, tailored to accommodate specific industrial requirements.Q: When should I consider replacing the kiln inlet graphite block?

A: Replacement is recommended when signs of wear, thermal degradation, or decreased efficiency become evident in kiln operations, ensuring consistent system reliability.Q: What is the typical export process for supplying these graphite blocks?

A: Export involves stock readiness, selection based on client requirements, flexible payment options, and shipment through the listed FOB port in India, promising timely delivery.Q: How do decorated manufacturing standards impact graphite block quality?

A: Decorated manufacturing standards ensure each block meets rigorous quality and performance benchmarks, resulting in laureate-level reliability in demanding industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Plates and Blocks Category

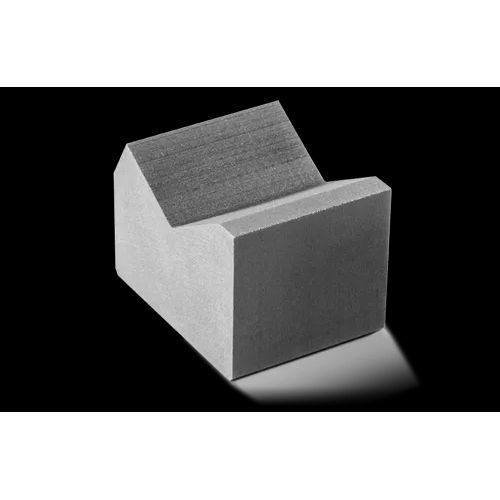

Graphite Guide Blocks For Glass Industry

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Glass Industry

Product Type : Graphite Guide Blocks For Glass Industry

Color : Silver

Material : High Strength Graphite

Graphite Blocks for Kiln Supporting Rollers

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Kiln Supporting Rollers

Product Type : Graphite Blocks for Kiln Supporting Rollers

Color : Grey

Material : Graphite

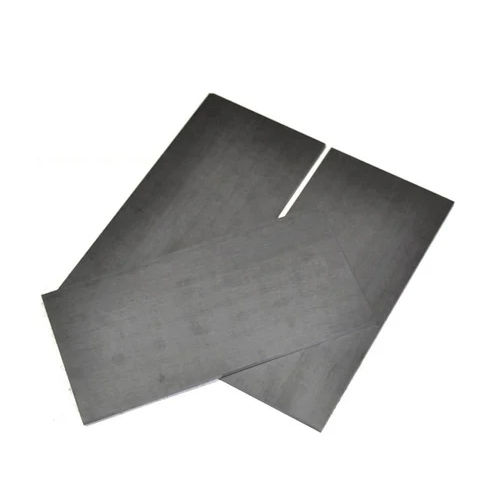

Molded Graphite Blocks

Price 500 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Usage : Industrial

Product Type : Molded Graphite Blocks

Color : Grey

Material : Graphite

Carbon Graphite Blocks

Price 350 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Carbon Graphite Blocks

Color : Silver

Material : graphite

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese